Checking Out the Crucial Applications and Use Aluminum Factory in Modern Production

Light weight aluminum foundries play a vital duty in modern manufacturing, serving diverse markets with their one-of-a-kind homes. From vehicle components that boost fuel efficiency to aerospace frameworks that focus on weight, aluminum's flexibility appears. Its applications reach building and construction and consumer electronics, highlighting its toughness and energy effectiveness. The developments in light weight aluminum spreading methods and future patterns call for a closer assessment, as they may redefine its impact on manufacturing.

The Duty of Light Weight Aluminum Foundries in Automotive Production

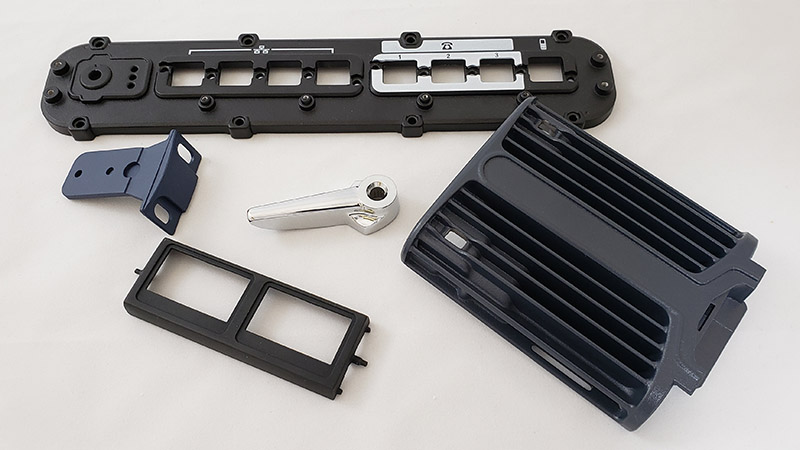

As the vehicle market increasingly prioritizes light-weight materials to enhance gas performance and performance, aluminum shops have actually become necessary contributors to manufacturing procedures. These factories specialize in generating elements that meet the stringent needs of contemporary vehicles, such as engine blocks, transmission real estates, and structural aspects. Light weight aluminum's desirable buildings-- such as high strength-to-weight proportion, corrosion resistance, and superb thermal conductivity-- make it a suitable choice for auto applications.

Aluminum shops use innovative casting methods, consisting of die casting and sand spreading, to create resilient and detailed parts. This ability permits manufacturers to enhance layouts for performance while lessening weight. The usage of aluminum likewise sustains sustainability goals, as it is extremely recyclable and lowers energy consumption in automobiles. By helping with the combination of light weight aluminum right into automotive style, factories play a crucial role fit the future of the vehicle sector, promoting effectiveness and technology across the board.

Aerospace Applications: Lightweight Solutions for Flight

Aluminum factories play a significant function in the aerospace field, where the need for lightweight materials is critical for improving fuel effectiveness and efficiency in airplane. The one-of-a-kind residential or commercial properties of aluminum, including its high strength-to-weight ratio and rust resistance, make it an optimal option for numerous aerospace parts. These parts consist of architectural components, engine coverings, and landing gear, which add to general aircraft performance.

The usage of light weight aluminum alloys, specifically those established via innovative spreading strategies, permits for the manufacturing of detailed layouts and intricate forms while lessening weight. Furthermore, aluminum's recyclability aligns with the aerospace sector's sustainability objectives, minimizing environmental impact. With continuous advancements in light weight aluminum factory innovations, producers can optimize manufacturing processes, resulting in increased performance and lowered costs. As the aerospace sector significantly focuses on developments that boost efficiency, aluminum shops will certainly remain indispensable to establishing lightweight remedies for contemporary flight.

Structure and Building: Enhancing Architectural Stability

In the building and building and construction market, a significant emphasis is put on boosting structural honesty with making use of light weight aluminum. Known for its high strength-to-weight proportion, aluminum gives longevity without jeopardizing on weight, which is critical in modern-day architectural layouts. Its resistance to rust further ensures longevity, making it an ideal product for different architectural elements, including beam of lights, frames, and cladding.

Light weight aluminum additionally assists in innovative style opportunities, allowing engineers and engineers to create visually pleasing structures while preserving safety and security standards. The material's convenience enables its application in both business and residential jobs, from high-rise buildings to bridges. In addition, advancements in aluminum factory methods have actually boosted the accuracy of light weight aluminum components, ensuring they meet strict structure codes. On the whole, the integration of aluminum in construction not only improves architectural honesty but also contributes to sustainable building practices, given its recyclability and energy-efficient production techniques.

Consumer Electronics: The Surge of Aluminum in Technology

In the domain name of customer electronic devices, aluminum has actually acquired importance because of its lightweight design advantages and superior thermal conductivity. This change not just boosts product mobility but also improves tool efficiency by successfully dissipating warm. As innovation continues to evolve, the duty of light weight aluminum in producing reliable and sleek devices is significantly considerable.

Lightweight Design Benefits

As consumer electronics advance, the need for lightweight yet sturdy products has risen, making light weight aluminum an increasingly popular selection among manufacturers. Its reduced density permits for the development of sleek tools that are simple to use and lug, significantly enhancing transportability. The strength-to-weight ratio of light weight aluminum guarantees that items can endure daily deterioration without compromising efficiency. Additionally, the pliability of aluminum makes it possible for producers to make elaborate forms and forms, better adding to ingenious appearances and performance. This light-weight characteristic additionally plays an important duty in energy effectiveness, as lighter tools require much less power to operate. Therefore, light weight aluminum not only satisfies the evolving aesthetic needs yet likewise lines up with the modern-day concentrate on sustainability in customer electronic devices.

Thermal Conductivity Benefits

Thermal conductivity is a vital consider the performance of consumer electronic devices, and light weight aluminum excels in this domain name. Its high thermal conductivity enables efficient warmth dissipation, which is important for preserving optimal operating temperature levels in devices such as smart devices, laptops, and pc gaming consoles. By facilitating rapid warm move far from sensitive parts, light weight aluminum assists stop getting too hot, thus enhancing efficiency and prolonging device longevity. Additionally, the light-weight nature of light weight aluminum matches its thermal residential or commercial properties, making it a suitable selection for mobile modern technology. As manufacturers significantly focus on efficiency and power effectiveness, aluminum's role in thermal management comes to be much more considerable, causing its growing adoption in modern-day digital styles. This trend underscores light weight aluminum's value in consumer electronics technology.

Marine Sector: Rust Resistance in Harsh Environments

Deterioration resistance is a critical variable in the aquatic market, where equipment and frameworks are consistently subjected to severe deep sea atmospheres. Aluminum, specifically in its alloy kinds, supplies considerable advantages in this regard. Its all-natural oxide layer supplies a protective obstacle that stops corrosion, making it ideal for vessels, anchors, and other aquatic applications.

Marine-grade light weight aluminum alloys, such as 5083 and 6061, are specifically designed to withstand the harsh impacts of saltwater and climatic conditions. These alloys not just resist corrosion yet likewise maintain architectural integrity and toughness gradually. Applications range from hulls and superstructures of ships to parts in offshore systems.

The lightweight nature of light weight aluminum further improves its suitability, making it possible for enhanced gas effectiveness and convenience of handling - aluminum metal casting. As the marine sector continues to concentrate on resilience and efficiency, aluminum stays an essential material selection for resisting rust popular aquatic settings

Advancements in Light Weight Aluminum Casting Techniques

While standard light weight aluminum casting techniques have actually served the industry well, recent advancements are changing the landscape of aluminum manufacturing. Strategies such as 3D printing of molds and cores are getting grip, permitting fast prototyping and lowered lead times. This innovation makes it possible for producers to develop intricate geometries that were formerly difficult to achieve with conventional casting methods. Additionally, developments in die-casting innovation, including using high-pressure die-casting (HPDC), have enhanced the precision and surface finish of cast aluminum parts, leading to boosted efficiency in numerous applications.

The adoption of investment casting has actually permitted for higher design freedom and reduced product waste. Advancements in alloy structures are also significant, as they boost next page mechanical residential or commercial properties and corrosion resistance. On the whole, these advancements not only streamline manufacturing processes but additionally contribute to more lasting methods within the aluminum shop market, making it adaptable to the advancing demands of modern production

Future Patterns in Aluminum Factory Production

The future of light weight aluminum foundry manufacturing is poised for considerable transformation with automation, enhancing effectiveness and accuracy in manufacturing procedures. Sustainable techniques are increasingly ending up being a priority, as shops seek to lessen their environmental effect while fulfilling growing governing needs. Furthermore, innovations in alloy development will certainly enable the production of stronger, lighter materials customized for diverse applications, driving advancement in the sector.

Automation in Factory Processes

Sustainable Production Practices

A growing emphasis on lasting manufacturing practices is improving the future of light weight aluminum foundry manufacturing. Sector leaders are progressively embracing energy-efficient technologies and reusing initiatives to decrease waste and minimize carbon footprints. Making use of recycled light weight aluminum considerably decreases energy intake compared to primary light weight aluminum production, making it a favored choice for eco conscious suppliers. Additionally, innovative casting techniques are being established to enhance product efficiency and minimize emissions. Business are also buying renewable power resources, such as solar and wind, to power their operations sustainably. aluminum foundry. By integrating these methods, the light weight aluminum factory sector not only satisfies governing demands yet also reacts to customer demand for greener products, inevitably leading the way for an extra sustainable manufacturing landscape

Advanced Alloy Growth

Advancements in light weight aluminum alloy growth are set to play a considerable duty in the future of shop production, especially as sustainability and efficiency needs escalate. The market is progressively concentrating on developing high-strength, lightweight alloys that can endure severe problems while decreasing environmental impact. Researchers are checking out cutting-edge make-ups, such as aluminum-lithium and aluminum-scandium alloys, which assure enhanced mechanical buildings and reduced weight. Additionally, the combination of sophisticated manufacturing methods, consisting of additive production and accuracy spreading, enables more complex geometries and decreased material waste. As regulative pressures and consumer preferences shift towards greener choices, the growth of recyclable and energy-efficient alloys will be crucial. The future landscape of light weight aluminum shop manufacturing pivots on these advancements in alloy technology.

Often Asked Concerns

What Are the Environmental Impacts of Aluminum Shop Procedures?

Light weight aluminum factory procedures can lead to significant environmental influences, consisting of greenhouse gas discharges, energy consumption, and waste generation. In addition, inappropriate management of pollutants might cause soil and water contamination, affecting neighborhood ecosystems and neighborhoods.

Exactly How Does Aluminum Recycling Affect Foundry Processes?

Light weight aluminum reusing enhances shop procedures by offering a cost-effective resources, minimizing energy intake and discharges. This sustainable technique boosts efficiency, reduces waste, and sustains the circular economy, profiting both producers and the setting.

What Precaution Are Carried Out in Aluminum Foundries?

Light weight aluminum foundries carry out numerous safety actions, including individual protective devices, proper ventilation systems, normal security training, fire avoidance protocols, and devices maintenance procedures to decrease risks and assure a safe functioning setting for all employees.

Exactly How Do Foundries Ensure Quality Assurance in Light Weight Aluminum Casting?

Factories assure quality assurance in aluminum spreading via extensive product inspections, exact temperature level monitoring, standardized procedures, and normal screening of cast products. These procedures aid maintain consistency, lower defects, and meet market requirements properly.

What Are the Cost Elements in Light Weight Aluminum Shop Manufacturing?

Cost consider aluminum factory production consist of resources rates, power intake, labor prices, equipment maintenance, and overhead expenses. Additionally, production volume and complexity of designs significantly influence general production expenses and earnings.

As the vehicle sector significantly focuses on light-weight materials to improve fuel efficiency and performance, aluminum foundries have actually come to be crucial factors to making procedures. Aluminum factories play a significant role in the click reference aerospace sector, where the need for light-weight materials is critical for enhancing gas performance and efficiency in aircraft. Additionally, advancements in aluminum shop methods have improved the accuracy of light weight aluminum elements, ensuring they fulfill rigid building codes. While traditional light weight aluminum casting methods have actually offered the industry well, current advancements are transforming the landscape of light weight aluminum manufacturing. The use of recycled light weight aluminum significantly decreases power consumption contrasted to main light weight aluminum production, making it a preferred selection for environmentally aware makers.